Product slotting can significantly improve warehouse productivity—and reduce labour costs by up to 30 percent. Simply put, product slotting is about putting the right product in the right place so you can pick it in the most efficient way…

Product slotting can significantly improve warehouse productivity—and reduce labour costs by up to 30 percent. Simply put, product slotting is about putting the right product in the right place so you can pick it in the most efficient way…

Over a relatively short period, a transport or fleet manager’s ability to support an efficient distribution network through route and delivery optimisation has shifted from almost nil to almost limitless…

In today’s competitive landscape, optimizing business operations is crucial, especially in the realm of logistics. Every company in this field is constantly searching for ways to streamline processes, reduce costs, and improve efficiency…

For many organisations, the reality of supplier performance management is that time and opportunity to track and react to dozens of complex KPIs simply doesn’t exist…

Customer and product profitability might not seem like the most exciting topic—until you realize how much it affects your bottom line. Over the years, I’ve seen countless businesses lose money on customer orders without even knowing it, all because they lack proper visibility. The problem often gets shelved because it feels too difficult to fix. Addressing loss-making products or customers requires cross-functional collaboration, and that’s where things start to fall apart…

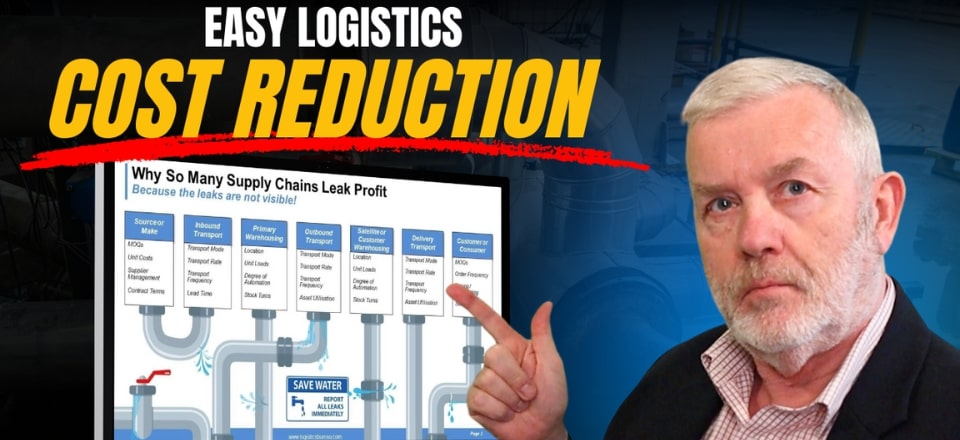

Reducing logistics costs can seem overwhelming, with so many factors to consider and constant pressure to deliver results. However, focusing on just on specific area can drive significant savings. Let me start by showing you a diagram that helps explain why logistics cost reduction can feel overwhelming. Imagine senior executives pushing you to cut costs, and you’re faced with so many areas to consider…

Does it take long to outsource logistics? The answer varies significantly depending on the operation…

Key Performance Indicators (KPIs) in logistics remain a critical and frequently discussed subject. First off, many people fall into the trap of tracking too many KPIs. My advice? Stick to three or four key performance indicators per level in your organization…

In today’s dynamic business environment, companies face several pressing challenges that impact their operational efficiency and cost management. Addressing these issues effectively can lead to significant improvements in performance and profitability…

Let’s dive into the current trends in logistics. You might be surprised by what’s capturing attention in the industry. During COVID, many businesses overstocked inventory to combat supply disruptions. Now, the focus has shifted to reducing excess inventory while managing tighter demand…