My 7 Golden Keys to Boost Your Knowledge of Supply Chain and Logistics

Avoid costly mistakes, make massive savings for your Business,

and enhance your career prospects with better pay rises and promotions!

Here are the seven basic ‘Golden Keys’ to getting a solid grasp on the Supply Chain knowledge that you need. If you are looking for a specific part of the process, simply click on the appropriate step below. Otherwise, continue reading after this list for all of the detail and links to resources you will need.

- Get a good grasp of Supply Chain concepts. It’s not Rocket Science, so get over it.

- Learn the basic jargon and terminology so you sound like an expert. It will make you more confident and gain the respect of others.

- Understand that Supply Chains vary a lot, from industry to industry and business to business. So get to know WHY they vary, and know how to drive lasting business improvement.

- Appreciate the ‘big levers’ in any Supply Chain. Those that make the biggest impact on cost and service. So you don’t waste time on the ‘little’ stuff that just drains your time and energy.

- Understand what KPIs are used in Supply Chain and why they are so effective in managing performance.

- Break through the technical ‘mine fields’ of transport and warehousing to the stuff that really matters and makes a big difference if you understand it. And most people don’t.

- Have a clear view of where you are now in your career, where you want to be in 10 years time, and your options to get there.

Key 1 – Supply Chain Concepts

OK, so let’s get you sounding like a real professional when it comes to Supply Chain. But first we need some basics. Let’s start with a definition of Supply Chain. There are many, but I quite like this one from Wikipedia. http://en.wikipedia.org/wiki/Supply_chain

A supply chain is a system of organizations, people, technology, activities, information and resources involved in moving a product or service from supplier to customer.

For commercial organisations, it’s also about providing appropriate levels of customer service to customers, at as low a cost as possible, to maximise profit margins. Think about a Supply Chain as including all the people and processes right from sourcing of raw materials through to delivering finished products to the customer or consumer. That covers a lot doesn’t it?

Have a think about the business where you work, or a business that you know well, and picture all the various functions and departments that support the Supply Chain.

- Procurement. Selecting and evaluation suppliers.

- Purchasing. Buying products and services.

- Transport. Arranging the collection from suppliers.

- Warehousing. Storing and maintaining the products before they are required for internal (maybe a factory) or external customers.

- Delivery or Distribution. Transporting the products to customers.

- Customer Service. Taking customer orders and passing these onto the warehouse.

- Inventory or Stock Management. Managing the amount of raw materials or finished goods that are in stock. Not too much, but just enough generally.

Now think about other businesses. Maybe businesses that supply YOU with products and services. They all have Supply Chains too.

Banks

They have to keep the ATM stocked with cash as well as the teller’s positions inside the bank (inventory management, delivery).

Hospitals

They have to manage not only patients, but all the equipment needed for patient care, and the drugs, the sheets and pillows, and so on. A massive supply chain operation.

Grocery Store

A classic supply chain. The grocery store or ‘retail chain’ needs to select suppliers for all the products. (maybe 30-40,000 products in a typical ‘Western style’ grocery retailer). They need to manage stock levels, order more from suppliers are required, store the product in warehouses until they are required then deliver them to the stores.

So what do Supply Chain managers and their staff try to do? What’s their purpose? Generally …. to get the right product, to the right customer, at the right time, in the right quantity, in the right condition, at the right (lowest) cost. That’s it in a nutshell.

So managing Supply Chain is a constant balancing act. Trying to maintain the right customer service, without incurring costs that are too high.

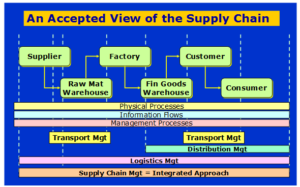

Now, you’ll hear terms like Supply Chain, Logistics and Distribution all used, sometimes in the same context. Most people get the differences wrong don’t worry. If you want to know what each really means, here we go:

Distribution

Usually means the outbound (customer side) of operations dealing with the warehousing and delivery of goods to customers. OK, that’s ones easy. At the time of writing, Wikipedia did not have a good definition of Distribution, just those relating to marketing and maths!

Logistics

This is a bit broader. http://en.wikipedia.org/wiki/Logistics It’s really about managing the flow of goods right from the point of supply, to the consumer. And it’s generally focussed around the physical movement and handling of the product.

Supply Chain

Then Supply Chain is even broader. How so? Well this definition from The Council of Supply Chain Management Professionals is a good one. “Supply Chain Management encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. Importantly, it also includes coordination and collaboration with channel partners, which can be suppliers, intermediaries, third-party service providers, and customers…” The rest of it is here http://en.wikipedia.org/wiki/Supply_chain

See how Supply Chain is much broader. It generally includes managing the external organisations too, like suppliers and transport companies.

So if you wanted a hierarchy of these terms, like in an organisational structure, it would go like this:

The Distribution Manager works for the Logistics Manager, who works for the Supply Chain Manager. Though except for very large companies, you would not expect to see all three of these managers in a company as the jobs can overlap a fair bit.

Key 2 – Jargon and Terminology

Like any specialist area in business, Supply Chain and Logistics has its own jargon. Lots of it. And it’s quite intimidating to hear all these terms at work and have no idea what they mean.

Things like.

DC. Distribution Centre, where product is stored ready to be delivered to customers.

MHE. Materials Handling Equipment, the equipment used in a warehouse to move large, heavy product around, such as Fork Lift Trucks (FLT)

S&OP. Sales & Operations Planning, which is really a communication system and discipline across all parts of a business to allow effective planning of supply and demand.

There are loads of these acronyms and abbreviations. Way too many to list here. So to make it easy, I’ll give you a complete glossary of all these key terms that you can view here: www.logisticsbureau.com/supply-chain-glossary/

Key 3 – Supply Chain Vary

Just like people and businesses vary, so Supply Chains vary. People new to Supply Chain tend to think that Supply Chain is Supply Chain no matter where and which business is involved. It’s not. At all. Let me highlight just two things that require very different Supply Chain approaches:

Geography

I’ve worked with businesses across many countries and the Supply Chain ‘solutions’ vary considerably. Let’s compare a business in the UK with one in Thailand. Maybe they are divisions of the same business. The type of product does not matter. But the UK company operates a highly automated warehouse. It stores product on pallets, in specialised racks, and the building is over 20 metres high. Special fork lift trucks are used that can lift the product to that height and because of the height, and the dangers involved with a swaying pallet 15 metres in the air, special super flat floors have to be used. These are very expensive and built to close tolerances to avoid the vehicles swaying.

The product is loaded onto trucks for delivery. Trucks that each hold 22 pallets of product.

This is a pallet. Pallets allow the trucks to be loaded really fast, using specialised fork lift trucks. The truck can be loaded in 15 minutes and then sent on its way.

Now let’s switch to Thailand. The same business and the same product. They have a warehouse that is only 4 metres high, and the product is just stacked up on the floor of the warehouse. No pallets. No pallet racking.

When a truck arrives to be loaded, twelve men start hauling the product by hand onto the truck, stacking it up as they go. The truck gets loaded to the roof in 40 minutes.

So why are the operations so different? Quite simply it is the cost base. In the UK land cost is very high. So a business can save money by building up, rather than out. A very high warehouse requires less land than the same size ‘storage cube’ in a lower building with a larger ‘footprint’. So the added expense of a high building and specialised fork lift trucks and super flat floors is more than off set by the lower land cost.

In the Thailand business, land is very cheap by comparison. And it makes no sense to invest in high buildings and specialised equipment, because just buying more land as more storage is required is a far cheaper option.

In the UK, fork lift trucks load the delivery vehicles. This means the vehicles are loaded faster (saving time and money for the truck and the warehouse) but also the forklift truck can do the work of 10 men if they were loading the vehicle by hand. And labour in the UK is very expensive. So labour saving equipment such as fork lift trucks can almost always be justified.

In Thailand the opposite is the case. I have worked out the numbers! I thought a fork lift truck would save time and labour. Wrong. 10 men are far cheaper than a fork lift truck. At least in Thailand.

So the message here, is to be aware of the environment of the Supply Chain. Things that work and make sense in one country, very often don’t work or make sense in another.

Business Type

Now different types of business have very different Supply Chains. Let’s make another comparison. These are real examples of companies I have worked with.

A Discount Clothing Retailer

This company needs to focus on keeping costs as low as possible and service high, or people will not shop at their stores. So they use cheap suppliers, based in China to make the products. (It’s all relative of course. China is cheaper than say the UK for production). They buy the product in large quantities to get bulk order discounts and they move the product by sea and then road to the retail stores.

The speed at which the products get from the supplier to the store is not too critical, as it is carefully planned in advance. So for the special ‘back to school’ promotion on kids’ shoes for example, the shoes were ordered to be made 6 months ago and will arrive in the retailers warehouses 2 weeks before the promotion starts. 2 days before the promotion, they will be delivered to the retail stores.

So you see the picture? Careful planning, a long time in advance and buying product cheaply and shipping it cheaply. It’s the only way for this business to stay in business.

Mining Spare Parts

OK, this company provides essential spare parts for mining machinery. Machines that cost $5 million each to buy. There are 10 of these machines operating in mines in remote areas, spread across hundreds of kilometres of rough country. And these machines will ‘lose’ the company $100,000 an hour in lost production if one of them breaks down.

The company that provides these essential spare parts will make sure that the parts are always available near where the machines operate. Or if one special part costs $500,000 each and tend to only fail once in 5 years, they might only stock 1 part but have a helicopter on standby to deliver it to the broken down machine as required.

Get the idea? The structure of a supply chain and the way it operates varies enormously. It varies because of a whole range of criteria that would also include supply availability, customer service needs and the like. And these things all vary depending on the country, the product, the business and the industry. So whilst some Supply Chain principles are common to most businesses, there are always elements that are unique and require a unique solution.

Key 4 – Big Levers

Give me a lever long enough, and a place to stand, and I will move the World. -Archimedes

Now if you want to sound and act like a real ‘pro’ in business, these will be gold for you.

Lever 1 – The Right Supply Chain Strategy

I’ve worked with hundreds of businesses around the World and I could count on the fingers of my hands, those that had a sound, well understood Supply Chain Strategy that supported the business goals.

Supply Chain Strategy is not hard, Establish what the business is trying to achieve. Then what the customers’ expectations are. Then find the best customer service outcome that you can provide, that still meets the needs of the business and any cost constraints. It’s not hard. Then communicate that clearly around the business.

The real trick is to make sure people are focussed on the right customer outcomes, and not on the ‘stuff’ that delivers the outcome. For example. Ensuring that 97% of customer deliveries arrive on time is a great outcome and focus. Not, being focussed on the next generation of shiny trucks that will deliver the product! They are just a tool to get the job done.

In fact, this is so important, and there’s a bit more to it that this, I’ll give you a chapter of one of my books that lays it all out for you. Download it right here. http://www.supplychainsecretsbooks.com

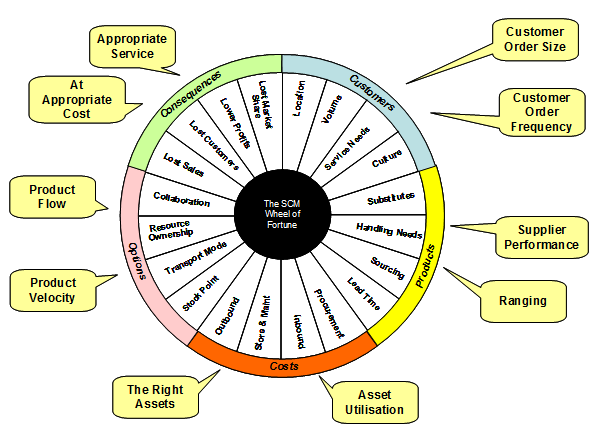

Lever 2 – Understand the Key Supply Chain ‘Drivers’

OK, that’s a bit too much consulting speak. So in plain English? What are the things that have the biggest impact on the Supply Chain? The ‘things’ that can massively increase costs or severely damage customer service? It’s not rocket science. It’s stuff like this:

Let me explain a couple. Customer Order Size. Think about the costs involved in processing a customer order. Customer service takes the order from the customer; they enter into an order processing system. The warehouse staff take the order and move around the warehouse to find the products and make up the complete order. It might for example have 8-10 items on the order. Then the truck driver collects the order, along with other customer orders and delivers it to the customer.

Now think for a moment. Let’s say we have two orders. One order has 2 items on it and the other order has 10 items on it. Will the larger order cost 5 times as much to process and handle? No way! Because there is a fixed resource and cost involved regardless of the order size. And then an additional small cost for every additional item on the order.

Let me put this another way, because it’s really important to understand this. Many people in business don’t!

You drive to the grocery store which is 10 kilometres away, park the car, go into the store, buy 1 product and then drive home again. The next day you make the same trip but this time you buy 10 products. Think about time it took you. The petrol you used in the car. If someone was paying you to do this, how many hours or minutes they would pay you for. Would it cost 10 times more to go to the store to buy 10 products? No way….

That is a vital lesson in managing supply chain costs. The larger and less frequent the orders are from customer, the cheaper they are to process and handle. An easy way to save loads of money in any business, is to tackle that problem.

Supplier Management is another key ‘Driver’. Consistent reliable supply is essential to maintaining an effective Supply Chain. If the products are not coming in at one end at the time and in the quantity required, you don’t ha a chance of keeping customers happy at the other end.

So it’s essential to manage and measure suppliers closely.

Lever 3 – Understand your customers’ needs

I wish I had a dollar for every business I had worked with, that had a one size fits all service policy. And I’ve yet to meet a business one size fits all makes any sense!

No business has a set of customers that all want or need the same thing. Just think about how customers vary in your business or a business that you know. I bet they vary by:

Their location. Metro v Rural. Easy to reach v hard to reach. Close to your warehouse v a long way away.

Their order profile. Some will order in very large quantities and some will place very small orders.

Their trading terms. Some will be happy to pay in 7 days, other at 30 days and yet others at 60 days. Some might pay cash on delivery!

See if you can create customer segments wit your customers. Each segment being a group of customers with similar needs and similar costs to service them. Understanding these is the first essential step to making big supply chain savings AND improving customer service.

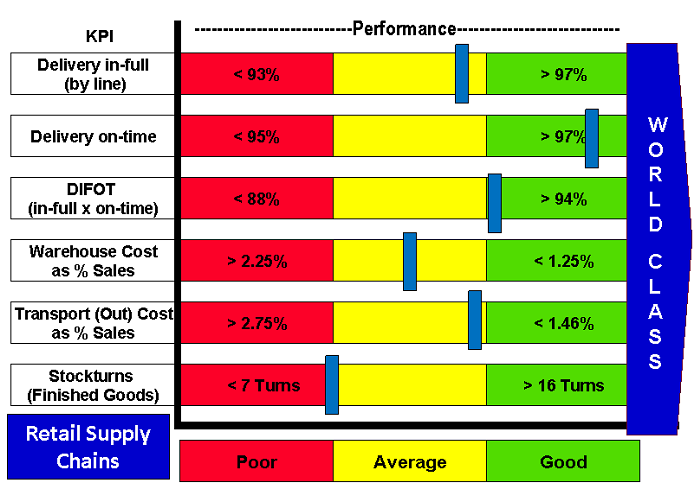

Key 5 – Key Performance Indicators

Many people get totally buried in literally book loads of Key Performance Indicators, more commonly referred to as KPIs. But if you want to grasp a good pragmatic approach to Supply Chain Management, there are only a few that really matter, at least at a high level. You can then break these down into more detail at each functional level like warehousing, transport and so on. But these are the essential ones:

Let me explain what they are:

Delivery in Full (By line)

Let’s assume that a customer placed an order with 10 lines. That is 10 different items. 9 of item A. 8 of item B, 24 of item C etc. Delivery in full by line would mean that each line (10 separate items) were all delivered in full, i.e. the quantity the customer ordered.

Delivery on Time

Fairly obvious. The order was delivered at the time required by the customer. Depending on how strict the delivery time was set by the customer, this could mean on the correct day, or even within a specific 30 minute ‘window’ on the day, as is quie common with grocery retail.

DIFOT

This is a combination of the two. All lines delivered at the right day/time.

Warehouse Cost as % of Sales

This is a high level measure of warehouse costs compared to the value (at sales price) of the products being sent out to customers. So for example if the warehouse sent out goods valued at $50 million in one year, and the total operaionf costs of the warehouse in the same year were $5 milion. Then our warehopuse cost as a percentage of sales was 10%.

Transport (Out) as a % of sales

Exactly the same as the warehousing cost calculation, but this time we are using the total cost of transport out. That is the transport that delivered goods from the warehouse out to customers.

Stock Turns (Finished Goods)

This is a measure of how efficiently we are using our finished goods stock. The faster we ‘turnover’ the stock, the less stock we actually have in our warehouse. This mean lower warehousing costs (less space required) and lower investment in stock. So a low number is good! So here’s an example. If we have a stock level that represents one months worth of sales, we have stock turns of 12. Or if we have a stock level that would be enough to cover one week of sales, we have 52 stock turns.

The coloured bands and figures on the chart merely represent poor performance (red) average performance (yellow) and good performance (green) for a specific industry. Obviously these figures vary by industry.

Key 6 – Transport and Warehousing

OK, let me give you some key principles of warehousing and transport to get you started.

Warehousing

In an ideal World we don’t need warehouses! Why? Because product would be shipped directly from our factories or supplies to our customers. But that ideal World rarely exists, because our customers want products fast and it takes too long to resupply directly like this. Also, our customer demand and the reliability of supply is not consistent. So that’s why we hold stock ion warehouses. So we can better meet customer demand.

Ideally a warehouse is fairly ‘dynamic’, meaning that product is coming in, being stored for a short time and then being sent out to customers. However in some industrial warehouses, holding things like spare parts, the products might sit awhile. The essential activities in a warehouse are: Receiving the product and checking it is the right quantity and quality.

Putting the product away, into suitable storage locations. Picking the product, that is going to ‘select’ the products to meet specific customer orders. Packing the products into suitable shipping containers. And finally loading the products or depatching them, onto vehicles for onward delivery.

So, what to look out for to look like an expert? For a warehouse to be efficient and effective, here are some things to check:

- That the time to Receive and Putaway products is not too long. The products cannot be used till they are registered onto the stock systems and put away in a ‘known’ location.

- That high turnover products are easier to get to, usually closer to despatch, than less frequently required products. It cuts down travel time around the warehouse.

- That people can ‘find’ the products when required! This means that an accurate location system has to be used.

- Is the type of storage appropriate to the product being stored, or are there lots of big ‘holes’ of fresh air. Imagine storing a 5kg bag of rice in a storage slot of 1 metre cube. Get the idea? Small things in small spaces, big things in big spaces. That way the whole warehouse space is better utilised. Typical warehouse storage systems might range from shelving for small items, to pallet racking for large items and lots of other types in between.

Transport

Lots of people don’t really appreciate how to effectively buy and manage freight transport services.

So let me give you some great tips from one of our transport gurus, John Cole. Here John reveals some of his ‘secret’ transport tips.

Essentially it’s about buying the right service level and at the right type of ‘rate’.

John’s easy to understand tips will have you knowing more than most…

Key 7 – Career Development Options

A career in Supply Chain and Logistics can be immensely satisfying and rewarding. But if you are starting out in your career, let me give you a few tips:

Qualifications

To progress into middle and senior management will often require professional qualifications. Ideally a degree in Supply Chain and Logistics, but just as useful are qualifications in Commerce, Finance and Marketing.

A lot of Supply Chain management is about understanding market needs and the cost/service trade offs involved in performance management. That’s why an understanding of finance is important.

If you already have qualifications in another business discipline, you ca learn enough about Supply Chain just from my mentoring program. No need for further university study.

Industries to Join

If you really want to gain World Class Supply experience I would suggest joining a large well known multi national in the areas of:

- Grocery Retail.

- Third Party Logistics

- FMCG (Fast Moving Consumer Goods)

Why? Because these industries have to be good at Supply Chain to compete in the market place.

Mentors

There’s an easy way and a hard way to get to the top. Smart people generally get themselves a ‘mentor’ early on. Someone with years of experience that you can learn from and who can help you avoid wasteing your time and energy. I have three key business mentors that help me in specific areas of my business life.

I hope you found this information useful. I certainly enjoyed writing and sharing it. But obviously there is far more to share than I can possibly cover here…

For those who want to learn even more and who are really serious about boosting their careers and Supply Chain capabilities, my mentoring program will cover topics such as these. This is just a sample as I have many more classes in production and will also be adding additional classes and materials for you to download based on member demand.

7 Ways to Supercharge the Supply Chain

Asia Consolidation

Benchmarking Performance

Chain of Responsibility

Cost Reduction Targets

Cost to Serve

CPFR

Customer Service Policy, write, set up, impact

Process Improvement

Demand Planning, Software

Business Case Preparation

Equipment Hire

Finance for Supply Chain

FMS/TMS

Freight Rates & Structures

Getting a Better Supply Chain Job

HR, Hiring, Firing, Labour Hire

Inventory Management

Jobs in Supply Chain

KPIs

Logistics Risks, Insurance, Marine Cover

Main SCM IT Systems

Managing Staff

Materials Handling Options

Negotiation

Network Concepts

Network Design

Offshore Sourcing

Optimising Inventory, ABC, Pareto, Customer Segmentation

Outsourcing Approache

Outsourcing Concepts

Prioritising

Procurement

Purchasing

S&OP Intro

SCM Accounting, Measurement

Slotting

Supply Chain Strategy

Supply & Demand Relationships

Terminology

Terminology & Jargon

Training & Qualifications

Transport Modes

Transport Outsourcing

Types of Supply Chain

Warehouse Contracts

Warehouse Design & Layout

Warehouse Operations

Warehouse Outsourcing

Which Associations to Join – Networking

WMS

Get Help with Supply Chain and Logistics

Everybody likes a secret. We just happen to like sharing them—at least the ones that will shorten your supply chain learning curve, save you grief, save your business money, and accelerate your career.