In this article, Logistics Bureau’s Mal Walker, who has spent decades exploring all aspects of warehousing, offers some valuable tips on warehouse design and operation.

Over the years, Mal has come to appreciate that there is real science behind distribution centre design, operation, and flow management. He has delved deeply into it and identified ten principles for optimising warehouse performance.

Let’s take a look at them one by one:

1) Minimal Touch of Goods

We want to get as close as possible to zero handling of products in the warehouse. Unless it is fully automated, the average warehouse will involve seven or eight instances in which products are handled. That means that people actually pick something up and put it down seven to eight times, either manually or using MHE. If you can get that down to three or four times your warehouse performance will improve.

2) One-Way Flow

One-way flow is really important, not only that of the goods in the warehouse, but also of vehicles around the warehouse.

One-way flow is a really good principle to apply during the design process because it allows you to plan your picking path through the warehouse as well as your replenishment paths.

In terms of vehicles, in Australia, we run trucks generally in a clockwise direction around the warehouse. The reason for this is so that drivers can reverse on the right side if they have to back into a dock. In the United States and many other parts of the world, it’s the other way around—counter-clockwise.

3) Triadic Warehousing

The vast majority of warehouses we see today are based on the triadic design—in other words, divided into three zones:

- Fast-moving product

- Medium-moving product

- Slow-moving product

A warehouse that has no zones would be non-triadic. But we may have both triadic and non-triadic in the same warehouse due to the increasing reliance on automation.

In the automated section of a warehouse, you don’t need to know where the stock is because the crane or the automatic storage and retrieval system will find it. But in the section that is operated manually, the correct placement of stock is critical.

4) Inventory Control

Inventory control is about having the right amount of stock to meet customer demand. We have to track the movement of products because that drives the physical process in the warehouse. It’s important to look at sales but also at the volume of the goods that are moving as well.

5) Efficient Labour

We have to optimise the labour that we’ve got. We do that by looking at the hours we’re putting into the distribution centre and measuring what the output is.

6) Benchmarking

Business benchmarking is seen as one of the smartest management tools around. We use this nifty process to measure our performance against that of peers and even competitors.

When it comes to warehousing, you need to determine the following:

- What would the best-in-class pick rates be for your warehouse?

- What are your rivals doing?

- How does your performance rate against industry standards?

7) Selecting the Materials Handling System

In this day and age, we’re seeing lots of what we call SKU proliferation. Companies are increasing the range of products that they are holding and it’s a real battle, because every time you increase the number of Stock Keeping Units (SKUs) you’re holding, you have to increase the logistics activity in the warehouse.

If you have a low number of SKUs and a low volume, you’re going to have a very simple materials handling system. It’s going to be very basic.

But, as the volume increases, you may start introducing a medium level of mechanisation. As your number of SKUs grows, you may start to consider mechanisation even if volume has not increased.

Sometimes the volume stays the same but the SKUs increase, as highlighted by the following example.

The Beer-on-Tap Example: In the old days, when you went into a pub you would have four or five beers on tap. Today, though, when you go into a pub you have a choice of 25 or more—and there’s probably about another 50 friends in the cabinet behind the bar—a very good example of SKU proliferation.

When we have a very high volume and a high number of SKUs, we may look at a highly mechanised system. You have to do some analysis to work out where you are and then choose the materials handling system to suit.

8) Know Your Data

This is where we look at all the transactional value data and information that’s coming in, such as:

- What we’re receiving

- What we’re picking, packing, and dispatching

- What we’re receiving in terms of returns

- Other value-adding activities

I’m going to tell you a secret now—never design your warehouse on averages.

If you design for averages, guess what? You’re going to be right half the time but wrong the other half. So we really have to look at the peaks and the troughs—and that’s where statistics come in. We need to use some mathematics to get things right.

9) Warehouse Management Software

It’s very important that you have a management system to help with the daily tasks, particularly as the complexity increases. You can spend a lot of money on a warehouse management system, but there are also some systems that are not so costly. These days even lower-cost systems support all types of radio frequency picking and also voice picking, where the picker wears a headset and works hands-free. Some of those technologies are really valuable.

10) Consult Widely

This one is critically important if we’re into a warehousing development project or just improving our current operations—we have to consult widely. Long gone are the days when we just have two or three people sitting in a room taking all the decisions.

You know, when I’m working with a company I’ll go and talk to the forklift driver, the receptionist, the managing director, and even the suppliers just to find out what’s going on and what the requirements are for that particular warehouse. People who are unloading containers at a dock will often tell you about the dynamics that they have to deal with on a day to day basis.

We also need to consult with architects, engineers, and environmental people. It’s important to consult widely so that we have inputs from many sources.

Some Tips on Warehouse Design

There are three methods of laying out a warehouse.

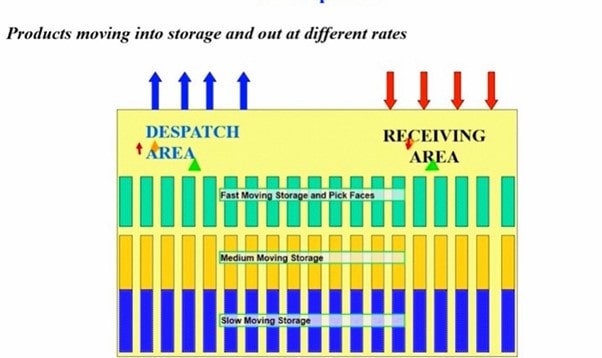

The U-Shaped Design

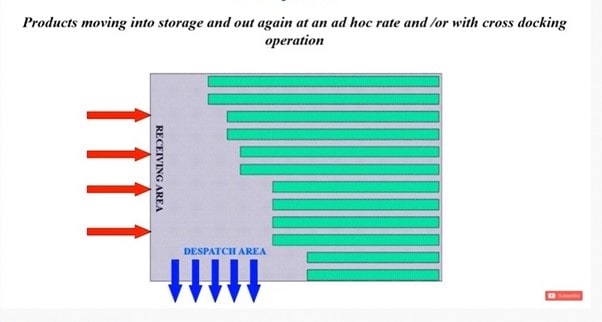

The picture above, a screenshot from a video of a seminar Mal gave on the subject, shows the U-shaped design, where you’re receiving in one area and dispatching from another.

This is a triadic warehouse. See how it’s laid out: fast, medium, and slow. The benefit of this design is that it has the docks at one end of the building and is the most economical from a land-use perspective.

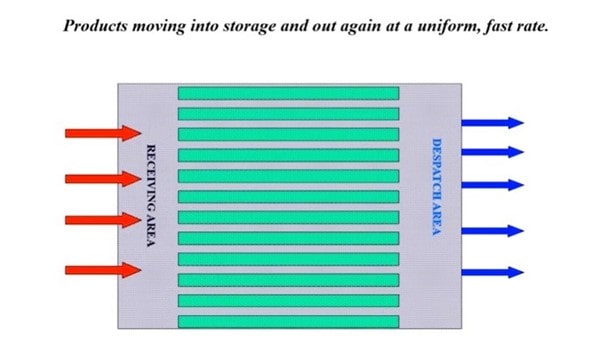

The I-Shaped Design

This one receives at one end and dispatches at the other end. This uses up more land because you have to have a hard stand at one end and a hard stand at the other. But it’s good if you have a high volume flow because you can get a lot of volume coming through here, and you’re separating the receiving and dispatch functions.

The L-Shaped Design

This is where you have receiving and dispatch in the same area. This design is really good for cross-docking, where we’re bringing stock in and then sending it out fairly soon after. We may never even put it into the racking. We bring it in and we dispatch it.

Now the interesting thing is that in some cases we may have two, or even three, of those designs in the one warehouse. It might be the case where you’re dealing with bulk goods coming into a warehouse and going out to a bulk customer.

If you have a wholesale network, you’re bringing stock in at one end, you cross-dock it, and send it out to a whole bunch of stores.

If it’s a retailer network, you’ll be bringing it in, putting it away, and then picking and packing it, and distributing it into small vans that are going around the city making deliveries.

We might actually employ all three of those in one warehouse, so it’s good to know them because the design and the requirement will determine what type and shape the warehouse will be.

The Importance of Slotting

Slotting is a very important part of your process. If you correctly slot product into the zones in a triadic warehouse, you can potentially achieve 20-30% percent savings in operating labour costs.

If you have a product in the wrong slot, you might find that you have long travel distances. Your inventory control is not there, you’re not rotating your stock. So it’s really important to slot the product correctly at the start according to the volume and the movement in the warehouse.

But once you’ve done that, we recommend that you revisit it once or twice a year. There is some really good software available to do that. You just feed in the transactions and the software will revise the layout of the warehouse for you. Once you know what the revised layout is, you spend some time moving stuff around and save maybe 20-30% of the labour cost.

Efficient Labour

I call it the overtime bug, and many companies suffer from it. So, why do people work overtime? Because they can put a few extra bucks in their pocket. But if it’s your warehouse and your staff are working overtime and you’re paying for it, that’s not good, is it? So what we try to do is work out just how efficient is our labour.

What we need to do is look at our normal hours of work versus overtime, look at the lines picked per day, and the number of cartons or pallets picked in the period. We can now use this formula to measure the order lines picked per labour hour.

If you want to know how you are doing, just look at the order lines picked per labour hour, per day, per week, or per month if you like. But you also need to compare that from period to period. That’s because if your order lines picked per hour is low but you’re working a lot of overtime, you need to say, “What’s going on? What are they doing? No one’s working during the day, they all work after five o’clock!”

Perfect Warehouse Design

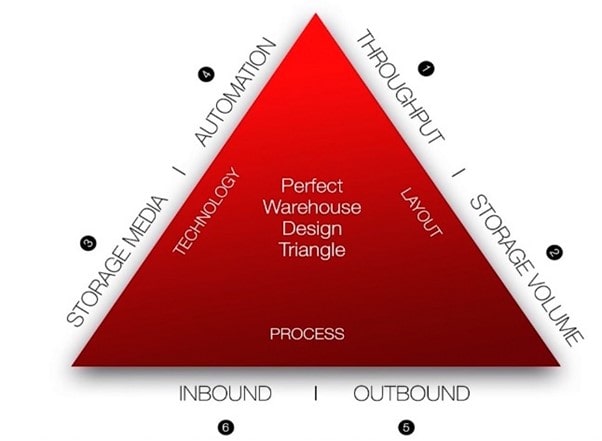

In terms of perfect warehouse design, the following three factors are involved:

Layout: Here we’re looking at the storage volume and the throughput. These are critical things so we need to get them right from the outset. If it’s an existing warehouse, sometimes we need to go back and check it because of possible increases in SKUs and volumes.

Process: This is related to the inbound and the outbound. A warehouse is just a box—it’s a buffer between supply and demand, that’s all it is. But we need to manage the inbound and outbound stocks effectively so that the process is as efficient as possible.

Technology: Here we need to decide: What is the storage media? What level of automation do we need to put in? We need to get that right.

If we’re able to balance all three aspects, we have every opportunity of getting the perfect warehouse design.

Subscribe to Our YouTube Channel

If you enjoyed this article, which is based on one of the many videos available on our Supply Chain Secrets YouTube channel, why not subscribe to the channel? That way you will be notified of our videos when they come out every Wednesday.

If you have any topics that you’d like us to cover on the channel, please leave a comment below. It’s really good to know what topics people like or don’t like.

Editor’s Note: This post was originally published on January 19, 2021, under the title “10 Proven Principles for Best Warehouse Design and Operation” on Logistics Bureau’s website.

Very nice

Glad you like it!